Spectacular Info About What Is The Difference Between Material Requisition Note And Bill Of Materials

Decoding Material Needs

1. What's the Fuss About Material Documents?

Ever feel like you're drowning in paperwork at work? Inventory management can definitely feel that way sometimes. But fear not! Understanding the difference between a material requisition note and a bill of materials can save you a whole lot of headache (and maybe even some money!). These documents are essential for keeping track of resources and ensuring projects run smoothly. Think of them as the dynamic duo of materials management, each with its own superpower.

Imagine you're building a birdhouse. One document tells you exactly what you need to build one birdhouse, down to the last nail. The other document is what you use when you actually need someone to go get those nails and wood from the storage room. Sounds like a pretty important distinction, right? Let's dive into the specifics.

At their core, both documents deal with materials. However, their purpose, timing, and scope are quite different. One is proactive, planning what's needed. The other is reactive, fulfilling an immediate need. Getting these straight will seriously help manage inventory and production flow effectively.

So, are you ready to demystify these documents? Let's get this show on the road!

Material Requisition Note

2. What is a Material Requisition Note?

Picture this: a carpenter realizes they're short on screws. They cant just yell across the workshop, "Hey! Throw me some screws!" Thats where a material requisition note comes in. It's an internal document, essentially a formal request to withdraw specific materials from storage or inventory. It's the "please and thank you" note of the materials world.

Think of it as a shopping list handed to the supply room clerk. It specifies the quantity and type of materials needed for a specific job or project. The person requesting the materials signs it, and so does the person who fulfills the request. This creates a paper trail, helping track material usage and prevent theft or misplacement. Its all about accountability, baby!

The note typically includes information like the date, requesting department, job number, a detailed description of the materials, quantity needed, and authorized signatures. The key is its reactive nature. It only comes into play when someone needs the materials right now.

Essentially, it's a crucial link in the chain, ensuring the right materials get to the right place at the right time. Without it, you'd have chaos, confusion, and probably a lot of half-finished birdhouses.

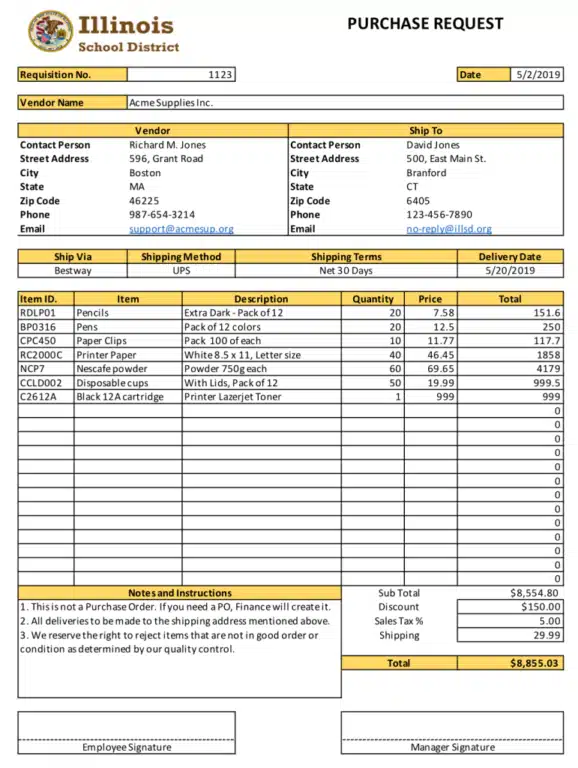

Purchase Requisition Note Format In Excel , Material

Bill of Materials

3. What's in a Bill of Materials?

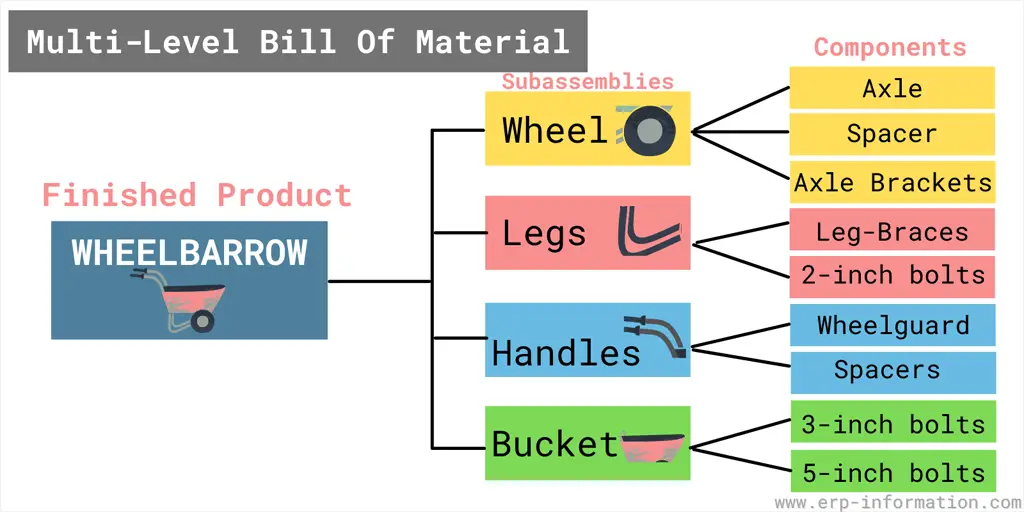

Now, let's talk about the bill of materials (BOM). This isn't a request; it's a blueprint. It's a comprehensive list of all the raw materials, components, and sub-assemblies required to manufacture a finished product. Its like a detailed recipe card, listing every ingredient needed to bake a cake.

The BOM is typically created during the design or engineering phase of a product. Its a proactive document, used for planning, purchasing, and production control. It's a vital resource for manufacturing companies, streamlining production processes and reducing errors. Think of it as the master plan that keeps everyone on the same page.

It contains a wealth of information: part numbers, descriptions, quantities, units of measure, and even the cost of each item. It can also include information on lead times, vendor details, and any special instructions for assembly. The level of detail can vary depending on the complexity of the product.

Imagine trying to build a complex machine without a BOM. You'd be guessing at what parts you need, ordering the wrong quantities, and generally creating a mess. The BOM provides clarity, accuracy, and efficiency, ensuring that the manufacturing process runs like a well-oiled machine.

![Free Printable Bill Of Material Form Templates [PDF, Excel] Free Printable Bill Of Material Form Templates [PDF, Excel]](https://www.typecalendar.com/wp-content/uploads/2023/05/bill-of-materials-example-pdf.jpg)

Key Differences Summarized

4. How Do They Differ?

Okay, let's nail down the key differences between these two documents. The material requisition note is a short-term, reactive request for specific materials. It's triggered by an immediate need and focuses on getting materials from point A to point B right now. It's all about fulfilling an existing demand.

On the other hand, the bill of materials is a long-term, proactive plan. It's a comprehensive list of everything needed to create something. It's used for planning, purchasing, and production control, ensuring that the entire manufacturing process is organized and efficient.

Think of it this way: the BOM tells you what you need, and the requisition note tells you when you need it. One is the overall strategy, the other is a tactical maneuver. Both are essential for effective materials management, but they serve different purposes and operate at different levels.

To make it even clearer, consider this analogy. The bill of materials is like a shopping list you make before going to the grocery store. The material requisition note is like asking a coworker to grab you a soda from the vending machine right now because you're parched. See the difference?

What Is The Bill Of Materials (BOM)? A Comprehensive Guide

Why Both Matter

5. How Can Companies Use These Documents?

So, why should you care about all this? Well, having a firm grasp of both material requisition notes and bills of materials can significantly improve your organization's efficiency and profitability. When used correctly, these documents can streamline your operations, reduce waste, and ensure that projects are completed on time and within budget.

A well-maintained BOM helps with accurate cost estimation, enabling you to price your products competitively. It also facilitates better inventory management, reducing the risk of stockouts or excess inventory. This, in turn, improves cash flow and reduces storage costs.

Using material requisition notes ensures that materials are used efficiently and that theres a clear record of where everything went. This helps prevent theft, waste, and errors. It also provides valuable data for analyzing material usage patterns and identifying areas for improvement.

In short, mastering these documents is a win-win. It's about working smarter, not harder. By implementing these practices, you'll be well on your way to materials management mastery!

FAQ

6. Your Burning Questions Answered!

Still got questions? No problem! Here are some frequently asked questions to clear up any lingering confusion.

7. Q

A: Absolutely! Even if you're not mass-producing widgets, a BOM can help you track the materials needed for each project, estimate costs accurately, and prevent mistakes. Its all about getting organized, no matter the scale of your operation.

8. Q

A: Uh oh, that's never good! Its crucial to regularly review and update your BOM to reflect any changes in design or manufacturing processes. If you find a discrepancy, investigate the cause, update the BOM, and make sure everyone is using the correct version. Communication is key!

9. Q

A: You bet! Plenty of software packages can help you create, manage, and track these documents. Look for solutions that integrate with your existing accounting and inventory management systems. This will automate many of the tasks and reduce the risk of errors.

10. Q

A: A good material requisition note should include the date, the department or person requesting the materials, a clear description of each item needed (including part number if applicable), the quantity required, the job or project the materials are for, and the authorized signatures of both the requestor and the person issuing the materials.

11. Q

A: This is a common issue! Ideally, your inventory management system should alert you to low stock levels before a requisition is submitted. However, if materials are unavailable, the requisition should be put on backorder, and the requestor should be notified of the expected delivery date. Clear communication prevents project delays!