Marvelous Tips About How Do Pilots Brake

How Do Pilots Brake? It's Not Quite Like Your Car!

1. Understanding Aircraft Braking Systems

Ever wondered how a massive airplane manages to slow down after hurtling down a runway at what feels like warp speed? It's not just a simple press of a pedal like in your car, that's for sure! Aircraft braking is a complex process involving multiple systems working together, and the pilots are expertly trained to manage it all. So, buckle up (figuratively, of course) as we explore the fascinating world of airplane brakes.

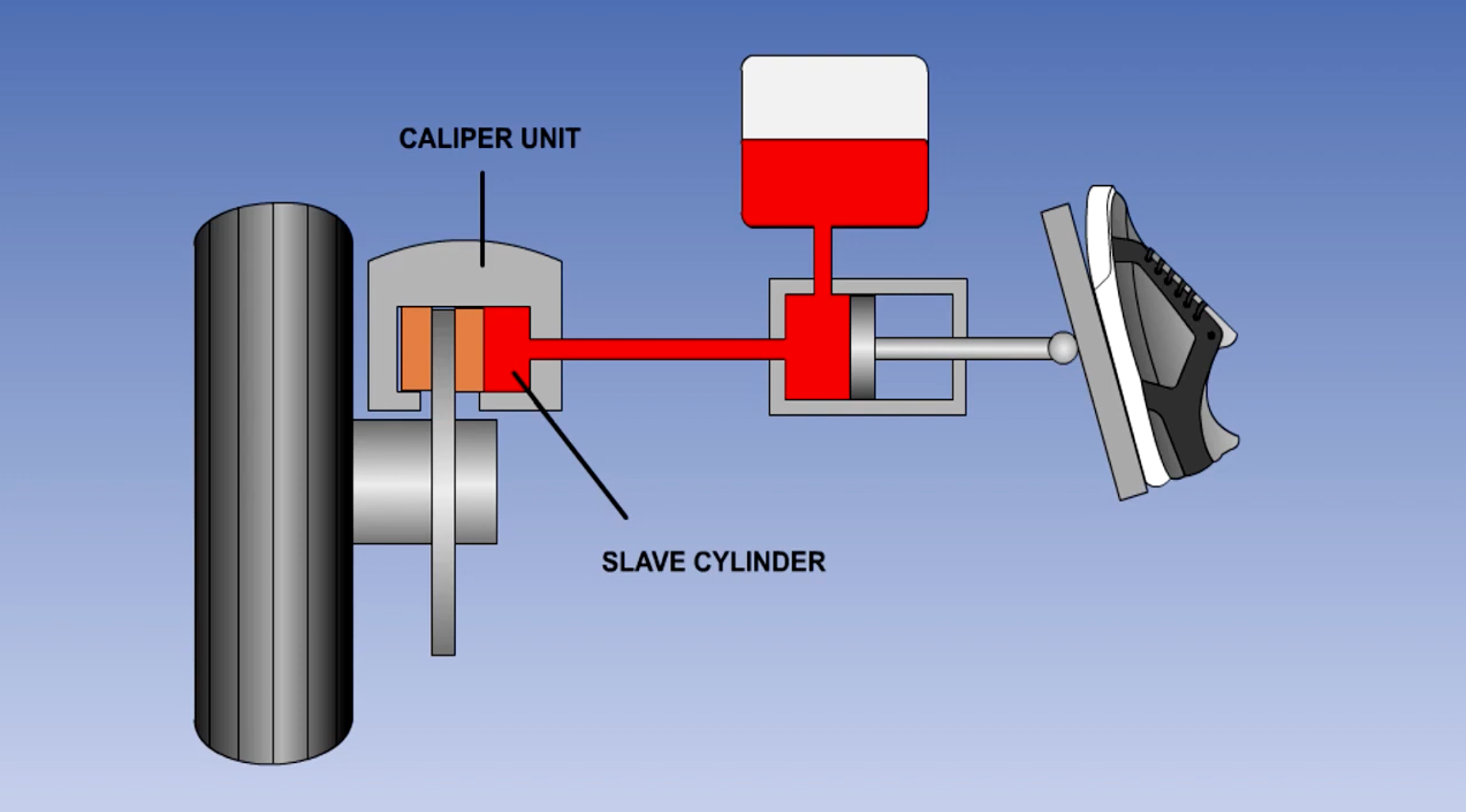

The primary system is the wheel brakes, which are located on the main landing gear. Think of them as super-powered versions of your car brakes. They use hydraulics to clamp brake pads against rotors attached to the wheels, creating friction and slowing the plane down. But unlike your car, the pilot doesn't just mash the brakes. They use a differential braking system, meaning they can apply different amounts of braking force to each wheel. This is super handy for steering during taxiing or correcting for crosswinds on landing. Imagine trying to parallel park a Boeing 747 — differential braking is your best friend!

Now, these brakes are incredibly strong, but relying solely on them after landing from a high-speed approach wouldn't be very efficient, or safe! That's where other braking methods come into play. These methods reduce the load on the wheel brakes and help the aircraft slow down quicker.

And get this, some larger planes even have carbon brakes! They're lighter and can withstand higher temperatures than steel brakes. They are important on planes that do a lot of short-hop flights with frequent landings and takeoffs.

Beyond the Brakes

2. Spoiler Alert

Wheel brakes aren't the only trick up a pilot's sleeve. Airplanes also use aerodynamic drag to help them decelerate. This is achieved through spoilers and thrust reversers.

Spoilers are hinged plates on the wings that deploy upwards, disrupting the smooth airflow and increasing drag. Imagine sticking your hand out of a car window — that sudden resistance you feel is similar to what spoilers do to an airplane. They're usually deployed automatically upon touchdown. Not only do they slow the plane down, but they also kill lift, ensuring the wheels stay firmly planted on the ground, which is rather important for effective braking.

Thrust reversers are even cooler. These redirect the engine's thrust forward, creating a powerful braking force. They're like putting the engines in reverse while still in the air (though they only activate after touchdown, for obvious reasons!). Different planes use different types of thrust reversers — some use clamshell doors that swing around the engine exhaust, while others use cascade vanes that redirect the airflow. Either way, the effect is the same: a whole lot of slowing down!

Combining wheel brakes, spoilers, and thrust reversers allows pilots to bring even the largest aircraft to a safe and controlled stop.

How Aircraft Braking Systems Work And Keep Cool

The Pilot's Role

3. Braking is an art, not just a science.

All these fancy braking systems are useless without a skilled pilot at the controls. Pilots are trained to use these systems efficiently and safely, taking into account various factors such as runway length, aircraft weight, wind conditions, and even the weather! It's a lot to think about.

Pilots typically use a combination of techniques to slow down. They might start by deploying spoilers and thrust reversers to quickly reduce speed, then gradually apply the wheel brakes as needed. The goal is to achieve a smooth and controlled deceleration without overstressing the brakes or causing discomfort to passengers.

They also have to be aware of something called "brake fade," which happens when the brakes overheat and lose effectiveness. To prevent this, pilots will often use lighter braking pressures or even use the brakes intermittently to allow them to cool down.

Its important to maintain directional control during braking, especially in windy conditions. Using differential braking can help with this, correcting for any tendency to veer off course. It's like a finely tuned dance between pilot, plane, and the elements.

Honda Pilot Front Brakes 20162022 How To Replace Brake Pads And

Automatic Braking

4. Automation Can Help, But Human Skill is Still Key

Many modern aircraft have an automatic braking system (autobrake) that can assist the pilot in slowing the aircraft down. The pilot can select different levels of braking force before landing, and the system will automatically apply the brakes upon touchdown. This can be particularly useful in low-visibility conditions or when the pilot is fatigued.

Autobrake systems use sensors and computers to monitor the aircraft's speed and deceleration rate, and they adjust the braking force accordingly. They can also detect and compensate for factors such as runway conditions and wind. Think of it as cruise control, but for landing!

But even with autobrake, the pilot remains ultimately responsible for ensuring a safe landing. They can override the system at any time if they feel it's not performing as expected. Automation is a great tool, but human judgment is always the final safety net. Its a pilot's job to monitor the systems and to be ready to take control at any time.

Of course, regular maintenance and inspections are crucial to ensure that the braking systems are working properly. Technicians perform routine checks on the brakes, spoilers, and thrust reversers to identify and fix any potential problems.

Honda Pilot Brake Fluid Change

So, Next Time You Land...

5. A newfound appreciation for aircraft braking

Next time you're on a plane landing, pay attention to the deceleration. You'll likely hear the thrust reversers kick in with a roar, and you might feel the subtle application of the brakes. And remember, a lot of goes on behind the scenes with pilots braking that you won't even notice. Aircraft braking is a fascinating combination of engineering, technology, and human skill that helps to ensure a safe and comfortable landing. It's a complex process that requires careful planning, precise execution, and a thorough understanding of the aircraft's systems.

Hopefully, this has shed some light on how airplanes slow down. Now, you can impress your friends and family with your newfound knowledge of aircraft braking systems! Just be careful not to bore them with all the details about spoilers and thrust reversers — unless they're aviation enthusiasts, of course.

Safe travels!

FAQ

6. Frequently Asked Questions about Aircraft Braking

7. Q

A: Nope! The wheel brakes only work when the wheels are on the ground. In the air, pilots rely on other methods, like adjusting the flaps and spoilers to increase drag and slow the plane down for landing.

8. Q

A: Aircraft are designed with multiple backup systems. Pilots are trained to handle brake failures using alternative methods, such as using aerodynamic drag and, in some cases, even ground looping (a controlled maneuver to scrub off speed, though it's a last resort!). Plus, runways have emergency arresting gear for extreme situations.

9. Q

A: Smaller planes often have simpler braking systems, typically relying primarily on wheel brakes. They might not have thrust reversers or sophisticated autobrake systems. However, the fundamental principles of braking remain the same — using friction to slow the aircraft down.

10. Q

A: Aircraft brakes are meticulously checked during routine maintenance inspections, following strict schedules mandated by aviation authorities. These checks include visual inspections, functional tests, and wear measurements to ensure optimal performance and safety.